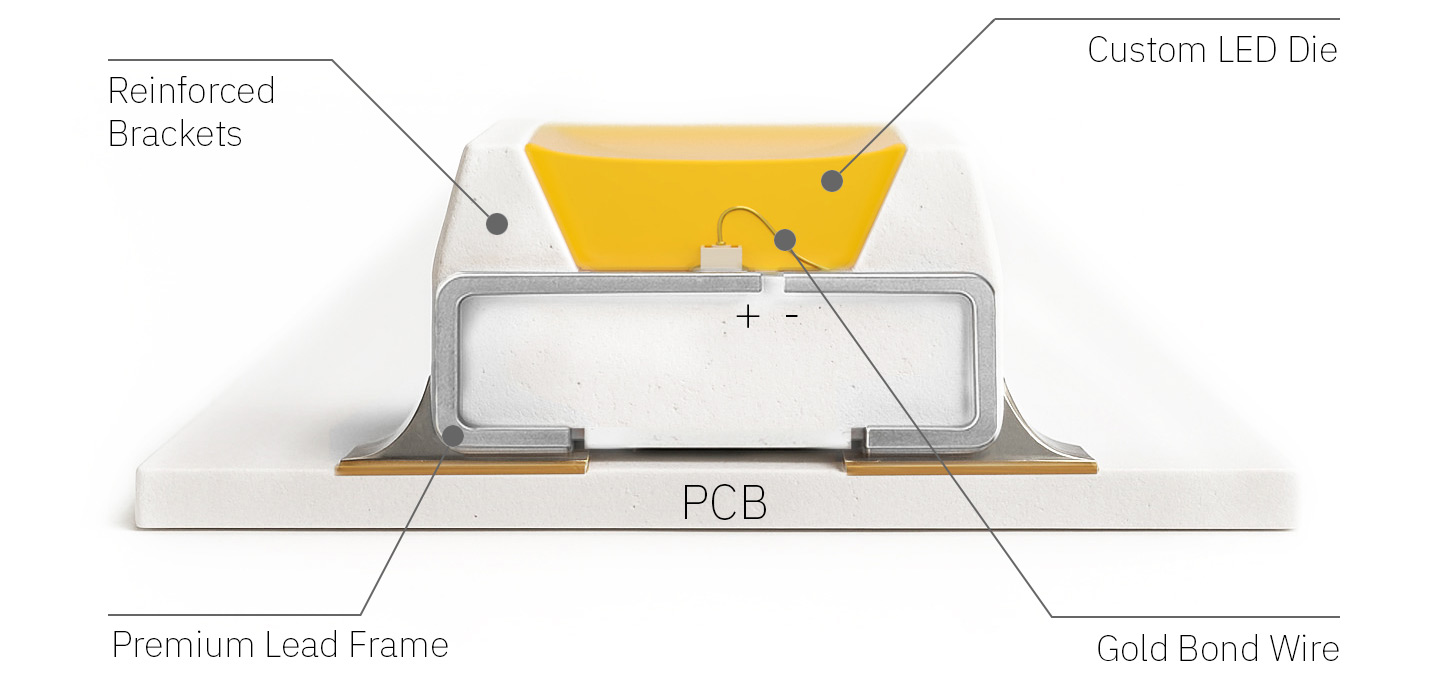

Some lighting brands buy off-the-shelf LEDs and call it a day. Not us. At Luminii, we engineer our own LED technology controlling every detail, from die to bracket.

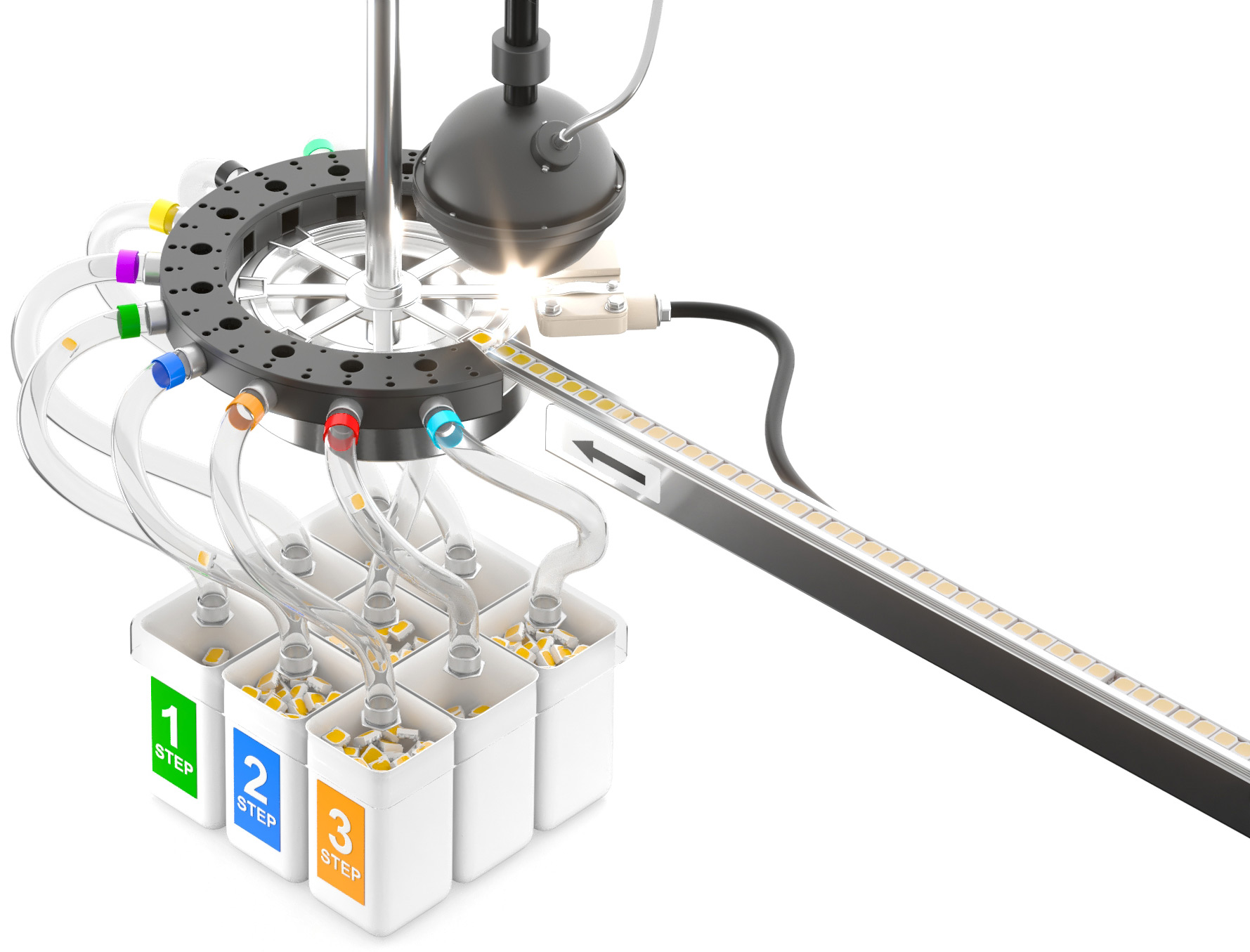

Custom LED Die: We start with a narrow band, 455nm custom LED die, underdriven at just 50% of its rated power. Why? More life, more efficiency, and the perfect match for our custom phosphor blend, giving you beautiful color and high-performance light.

Gold Bond Wire: We use 99.99% pure gold to connect our die, not a copper alloy like most. Gold means long-term reliability, less power loss, and virtually no degradation over time.

Premium Lead Frame: Made from high-purity copper and plated with 40μm of silver, our lead frame offers superior conductivity and moisture resistance.

Reinforced Brackets: Our bracket is built from high-grade Polyphthalamide (PPA) delivering:

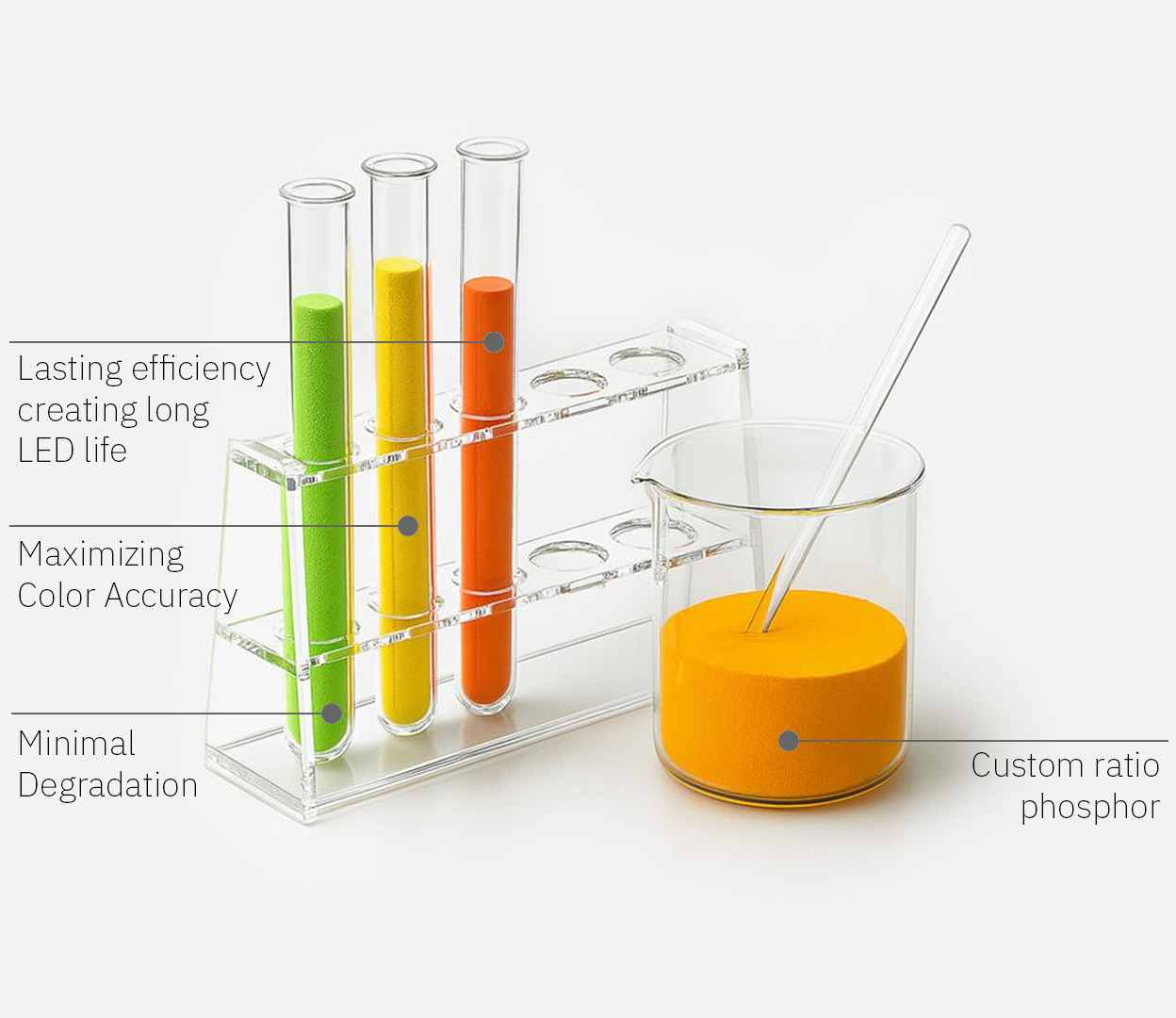

At Luminii, we create our own proprietary blend of nitride and aluminate phosphors engineered for maximum color quality, thermal stability, and efficiency that lasts.

Why It Matters

Phosphors impact everything: CRI, color consistency, and longevity. Our phosphors are designed to:

Controlling both the die and the phosphor means we get the best of both and so do you.

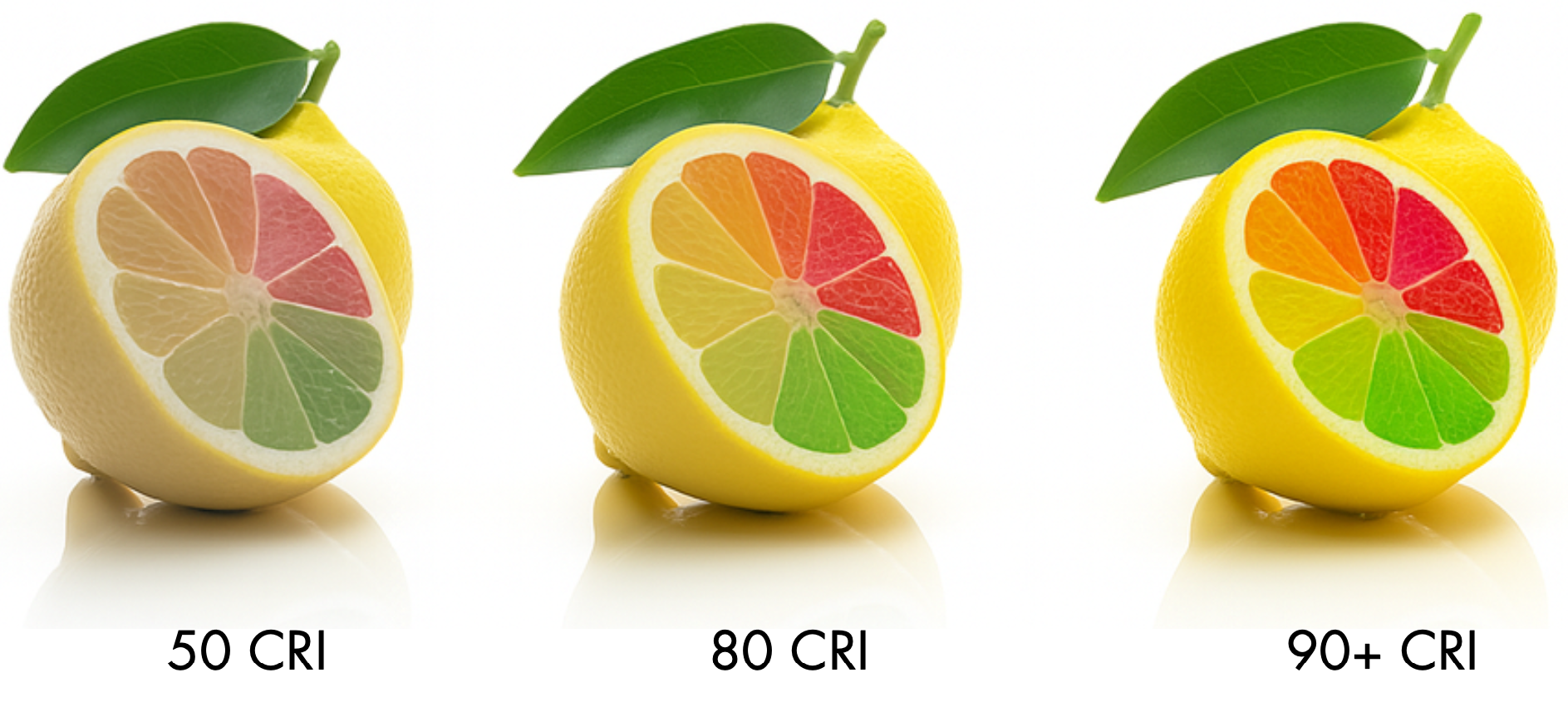

By evaluating TM-30 in conjunction with Standard and Extended CRI values, we develop LEDs that deliver balanced, high-quality light, accurately rendering colors, and closely mimicking natural light.

CRI (Color Rendering Index)

CRI quantifies how accurately a light source renders colors compared to a reference illuminant (incandescent for <5000K, daylight for >5000K). The metric ranges from 0 to 100, with higher values indicating better color fidelity. The standard CRI calculation (Ra) uses the average of the first 8 test colors (R1–R8), which are desaturated pastel tones. While useful, CRI does not account for saturated or red hues critical in many applications.

R1–R8 (Standard CRI Values)

Standard CRI values are used to calculate the average CRI. They measure how a light source renders common or pastel colors which are useful for everyday applications…but they don’t tell the whole story.

R9-R15 (Extended CRI Values)

These values go beyond standard CRI to evaluate how well a light source renders saturated or specific colors supporting applications that require high-quality lighting.

R9 Value: Measures how well deep, saturated reds are rendered. Important in medical lighting, skin tones, food, and art.

R13 Value: Evaluates how well light pinkish tones typical of Caucasian skin are rendered

R15 Value: Evaluates more golden or yellow-based skin tones, ensuring lighting looks natural across different complexions.

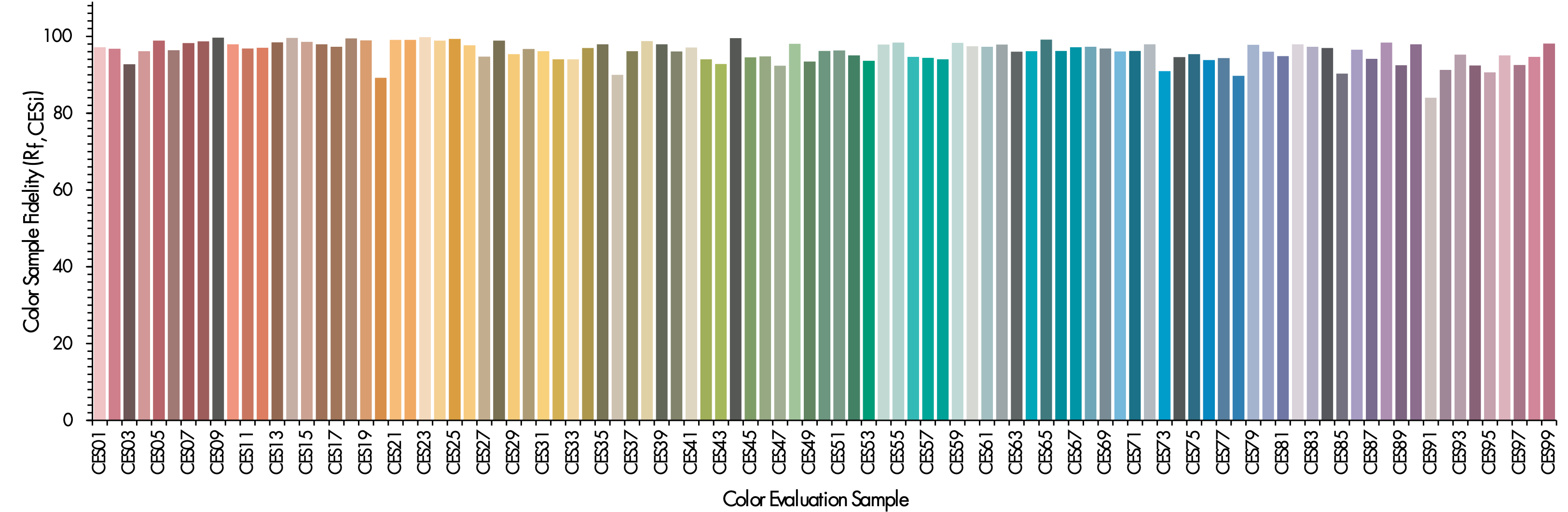

TM-30 is a modern color rendering metric designed to improve upon the older CIE CRI standard. Unlike CRI (which uses only 8–15 pastel colors), TM-30 analyzes 99 real-world color samples — covering a wide range of hues, saturations, and materials.

This results in a more accurate and realistic assessment of how light renders colors. TM-30 includes two key metrics:

It also provides detailed graphical tools to visualize color distortions and hue shifts.

TM-30 helps lighting professionals make better design decisions and enhances visual experience in various settings.

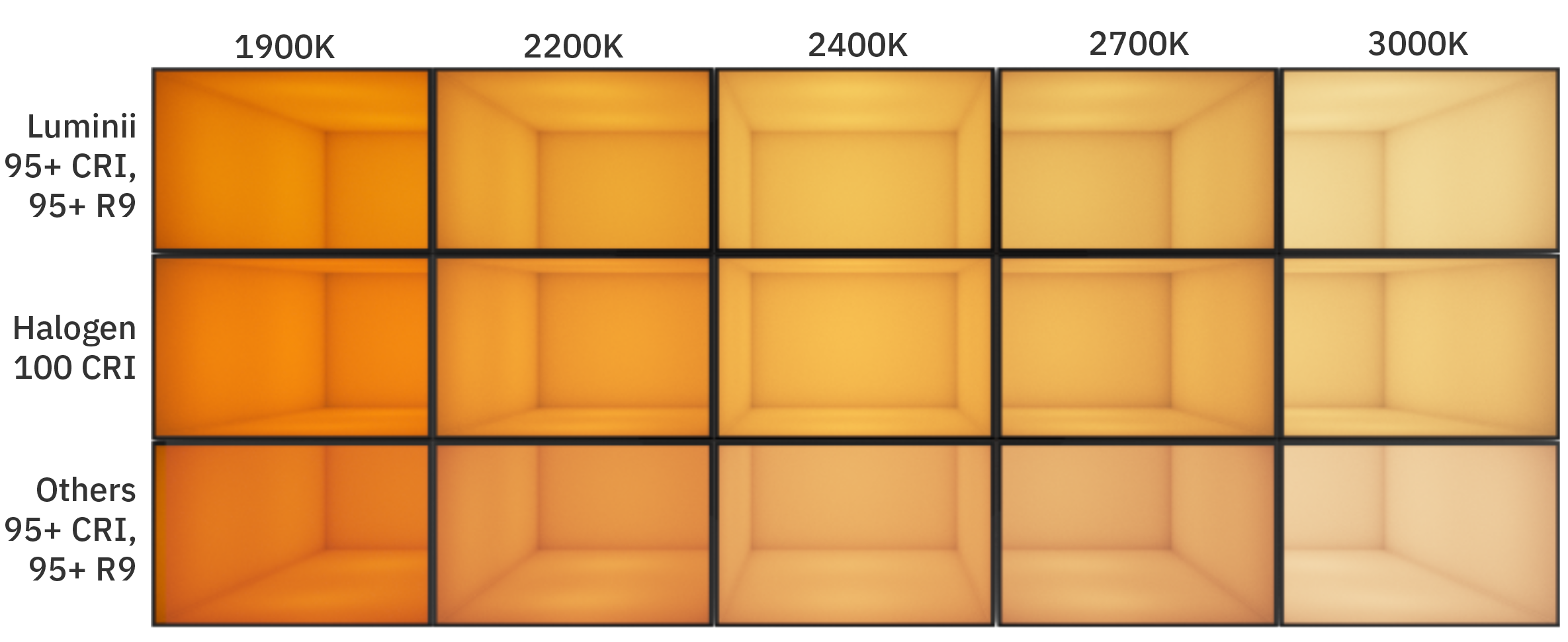

Inspired by Incandescence: Halogen lamps have long been the gold standard for warm, natural light with a perfect CRI of 100.

Human-Centric Appeal: Known for their ability to reveal rich reds and subtle warm tones, halogen light creates inviting, comfortable environments.

LEDs with Soul: Luminii replicates the visual warmth and color fidelity of halogen using advanced solid-state technology.

Precision Engineered:

More Than Just CRI: Our LEDs are designed to closely match the spectrum of natural daylight and halogen’s signature warmth—ensuring color consistency and emotional resonance across applications.

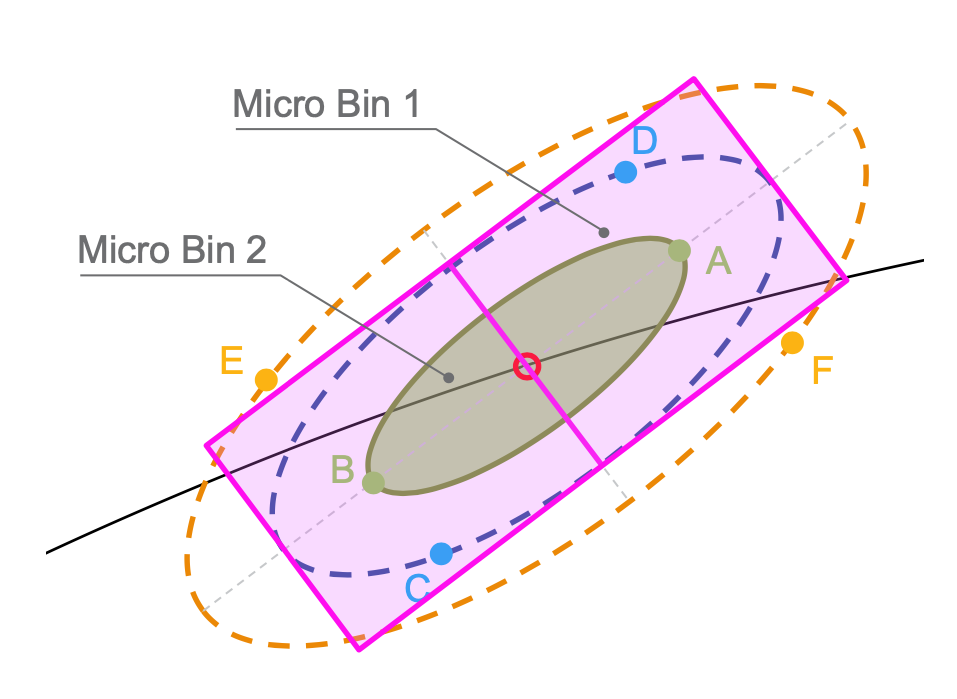

Binning is the process of grouping LEDs by color to ensure uniform output. At Luminii, we go beyond standard methods to deliver true 1-step MacAdam Ellipse performance across our linear strip lighting.

The MacAdam Ellipses, which define how close a group of LEDs is to a target color point. A 1-step MacAdam ellipse indicates the tightest tolerance, where color differences are virtually imperceptible to the human eye. 2-step or 3-step binning allows greater variation, which can lead to visible inconsistencies across a fixture or installation.

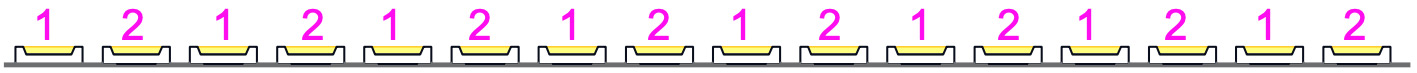

At Luminii, we implement a precision-driven approach to achieve true 1-step MacAdam Ellipse performance across our linear LED strip lighting. The process begins by sorting LEDs into multiple smaller micro bins based on their chromaticity (x, y) values, creating tighter control than standard binning methods.

Once sorted, the LEDs are strategically placed diagonally across the strip, matching chromaticity values in a way that balances hue and saturation. This technique ensures that the overall color output averages precisely to the target chromaticity point, minimizing visible variation from one end of the strip to the other.

What That Means:

How We Do It:

Paired with our custom phosphor blend and tuned LED die, this precision approach ensures flawless color rendering ideal for applications where light quality matters most.

Others: Many other lighting manufactuers just randomly take and place LEDs on their LED tape. While directly comparing two LEDs together, you may not notice a color difference, if you stack many LEDs from the same side of a MacAdams ellipse together on the LED tape, you may notice a slight color striations across the whole LED tape.

Others: Many other lighting manufactuers just randomly take and place LEDs on their LED tape. While directly comparing two LEDs together, you may not notice a color difference, if you stack many LEDs from the same side of a MacAdams ellipse together on the LED tape, you may notice a slight color striations across the whole LED tape.

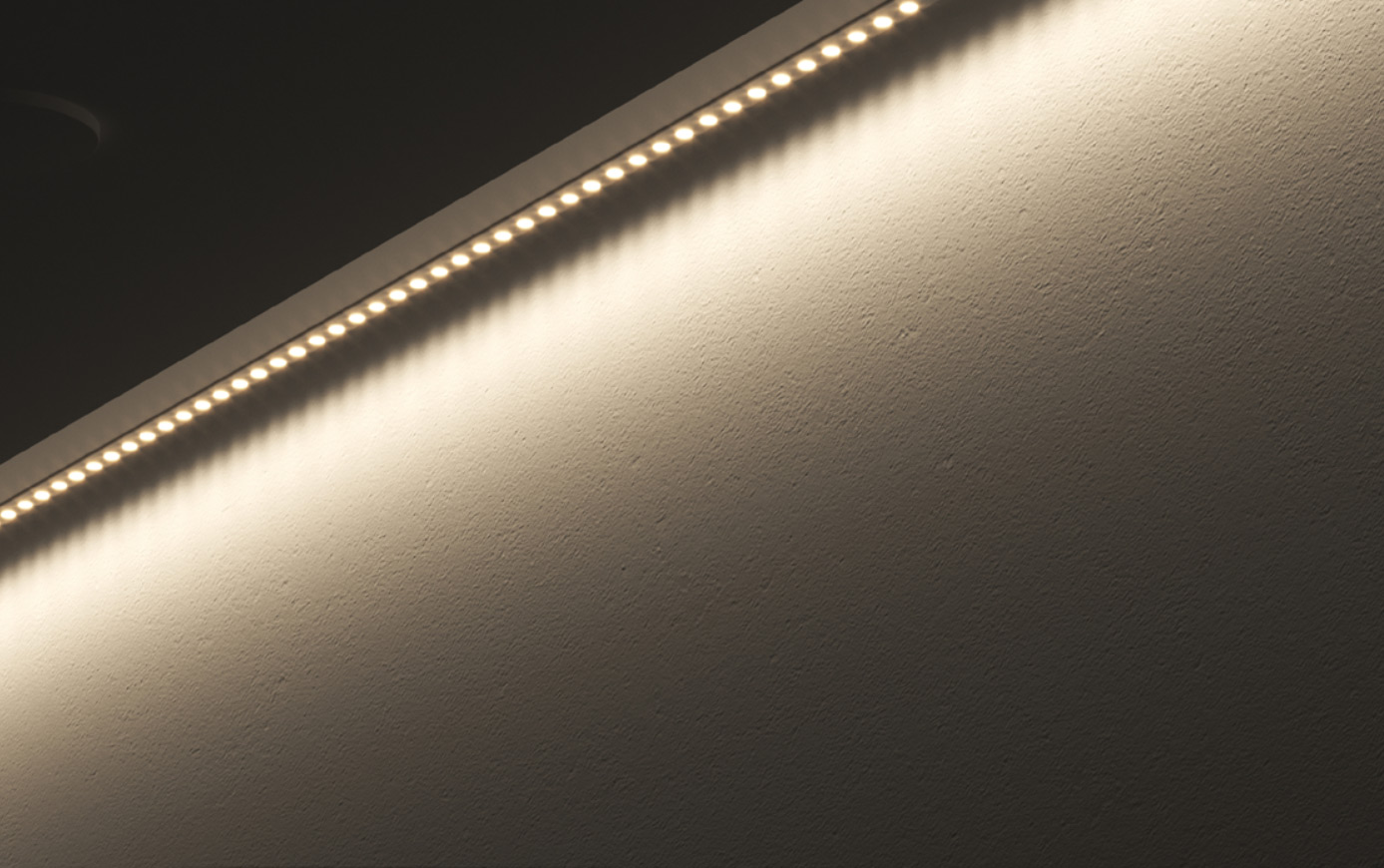

Luminii: Luminii meticulously places each LED on the LED tape using our micro bin processing so that there is color consistency across the entire LED tape, meaning the color at the beginning of the LED tape exactly matches the color at the end of the tape.

Luminii: Luminii meticulously places each LED on the LED tape using our micro bin processing so that there is color consistency across the entire LED tape, meaning the color at the beginning of the LED tape exactly matches the color at the end of the tape.

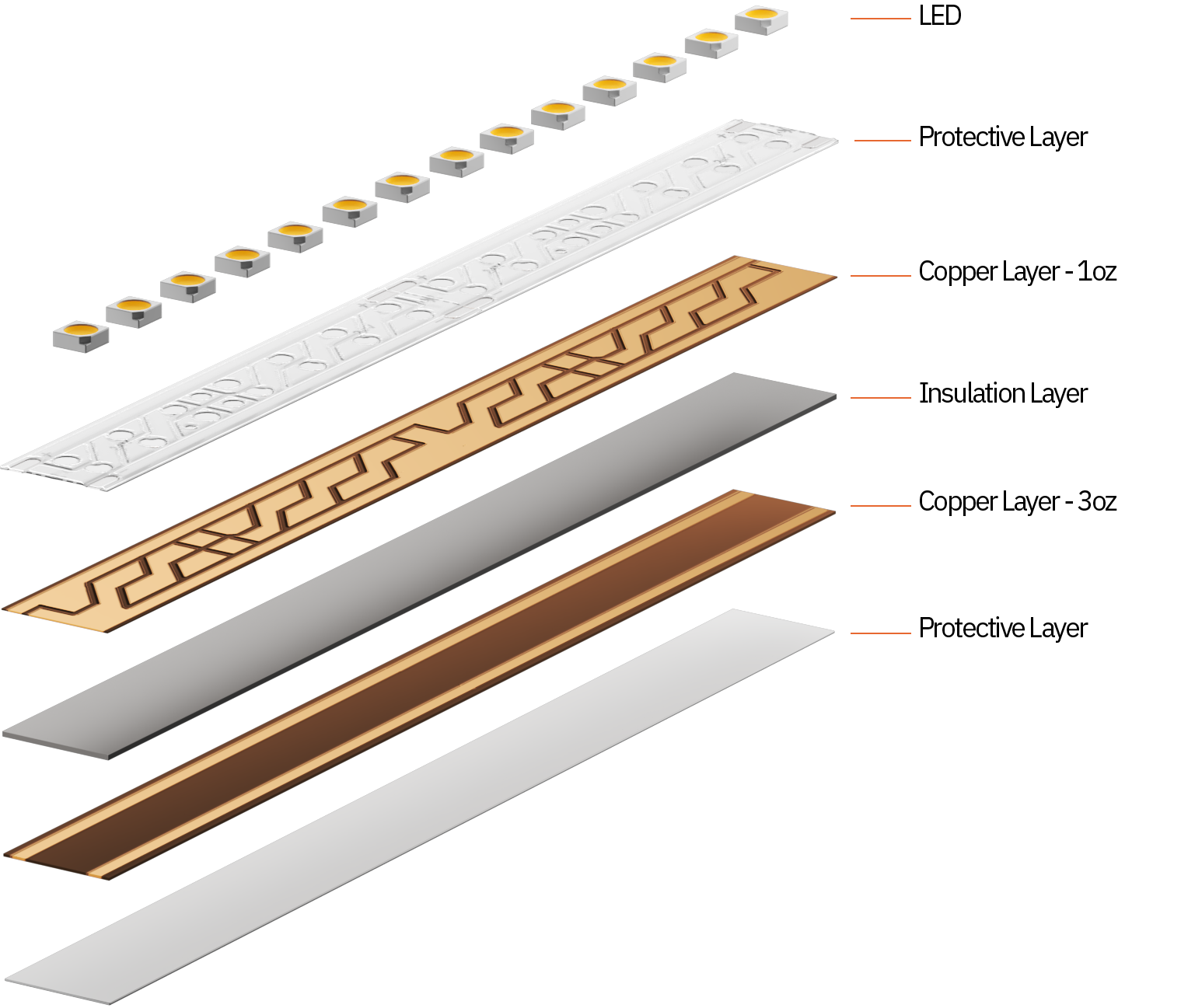

That’s why we design everything around our light engine, from the PCB, to the optics, to the extrusion, to deliver unmatched reliability, thermal performance, and architectural quality.

Benefits of Luminii PCB Design:

In-House Design: Custom-developed for linear LED systems using optical-grade, UV-stabilized polymers.

Durability Tested: Materials are exposed to 1,000+ hours of UV, heat, and humidity to resist yellowing, warping, or degradation.

Glare-Free Finish: Lenses feature custom diffusers and a matte surface to eliminate glare and reflections.

Performance Focused:

Color Accuracy Maintained: Preserves the original CCT and CRI for true-to-spec color rendering and clean architectural presentation.

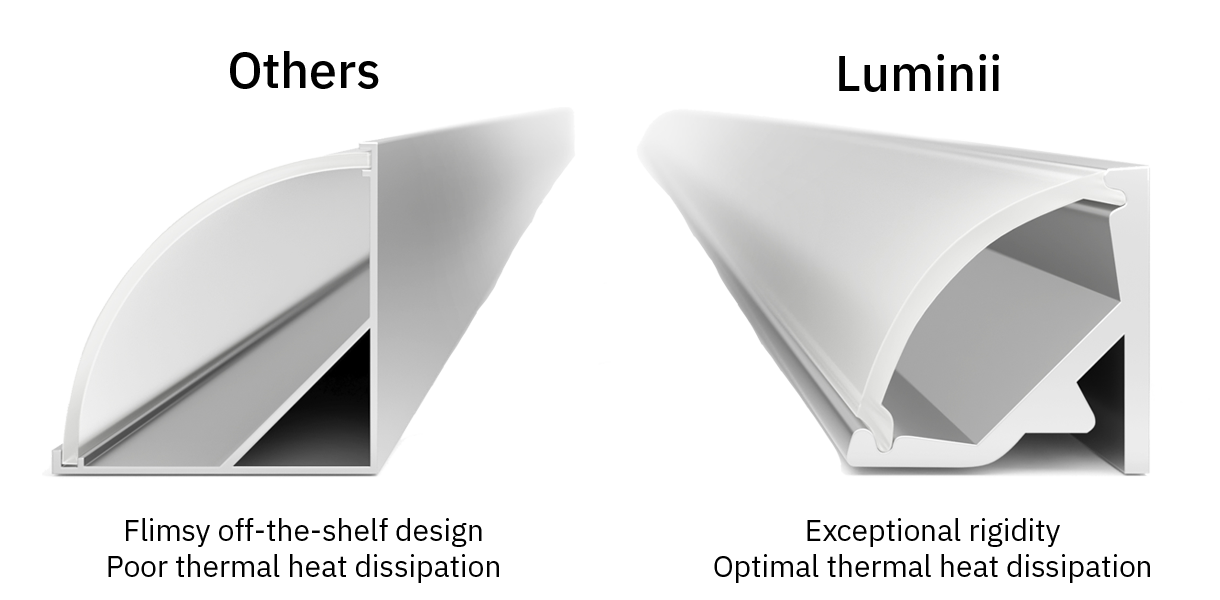

High-Grade Material: Made from 6063-T5 architectural aluminum for superior rigidity, thermal management, and optical alignment.

Structural Integrity: With a 0.035” wall thickness, profiles provide strong support and heat dissipation — ideal for long runs and high-output applications.

Installation-Ready: Extra rigidity maintains shape during handling, even when lifted from one end.

Performance-Tested: Each profile undergoes thermal and optical simulation to ensure cooling and light quality.

Architectural Detailing: Designed for clean integration with concealed mounting, flush endcaps, finish-matched components, and invisible hardware.

Made in the USA: Available in up to 12-foot lengths and the broadest finish range in the industry.

Where Precision Meets Aesthetics: Delivers both technical performance and a refined visual finish.